Ceramic analysis for proven quality

Technical ceramics gain more and more interest for special high-performance applications. Long living cutting tools, efficient catalysts and sensitive sensors are just a few of them. In many cases elemental concentrations of carbon, sulfur, oxygen, nitrogen and hydrogen influence greatly their functionality. Our inductar® series is specialized in accurate chemical analysis of highly temperature stable materials.

Flexible carbide analysis

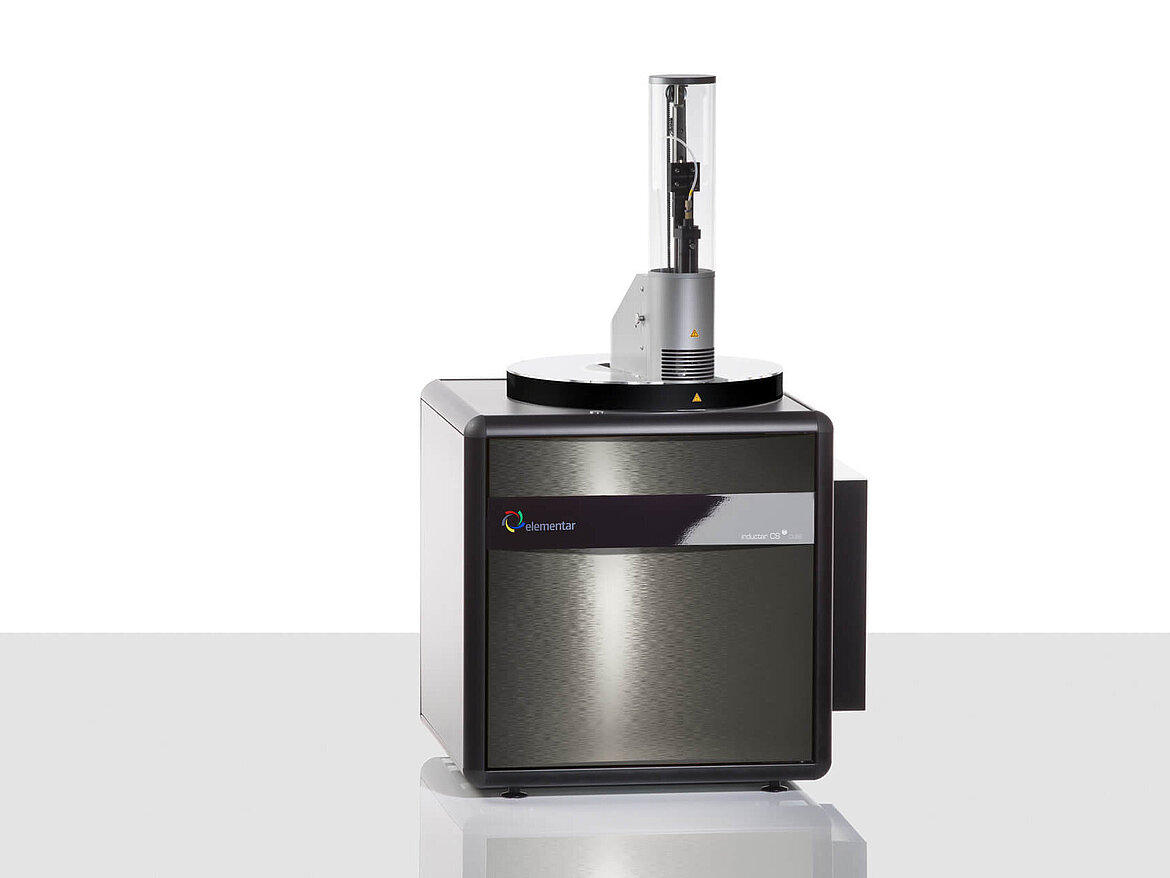

Chemical stoichiometry and oxidation of titanium carbides or tungsten carbides play crucial roles for production yield and product quality. The inductar® EL cubeis the world's first elemental analyzer, which is made for accurate carbon and oxygen determination from a few ppm to percent levels in one single instrument. Investing in one innovative solution instead of two separate instruments saves costs and reduces the needed laboratory bench space. Moreover, we developed an advanced crucible design which is ideal for clean combustion of ceramic powders. Thus, even highly reactive, fine powders can be combusted in oxygen atmosphere without any tedious cleaning operation. Furthermore, results are more accurate and reliable due to the clean combustion.

Accurate results for superior pure nitride properties

High performance nitrides are well known for their excellent mechanical or electrical properties. Titanium nitride and silicon nitride are extremely hard, gallium nitride is used for LEDs and boron nitride shows even similar properties like diamond regarding chemical and thermal stability. But all these fantastic properties are quickly ruined by additives and little impurities. Therefore, accurate chemical analysis is required for quality control to ensure these superior properties. Our innovative solid-state induction furnace enables temperatures up to 3,000 °C and ensures reliable and complete fusion and combustion for best measurement results.

Elemental analysis for exact monitoring

Chemical composition of oxides varies during production depending on process parameters. Depending on precursor materials and furnace atmosphere, e.g. carbon and oxygen concentrations are changed. Elemental analysis is the ideal analytical method to exactly monitor light elements like carbon, oxygen, nitrogen and hydrogen not only during production but already at development stages. Our inductar series is made for easy and accurate analysis of these elements, which are subject to changes during thermal processing. Thus, high performance ceramics are ensured by detailed composition control during both R&D and production as well.