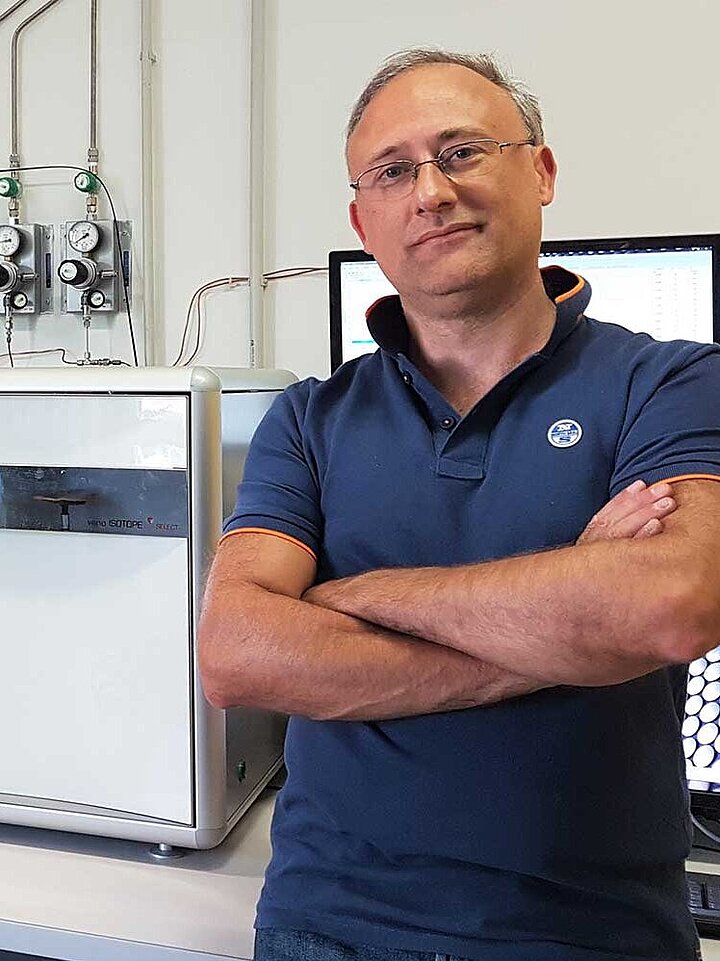

The workhorse in elemental analyzer isotope ratio analysis

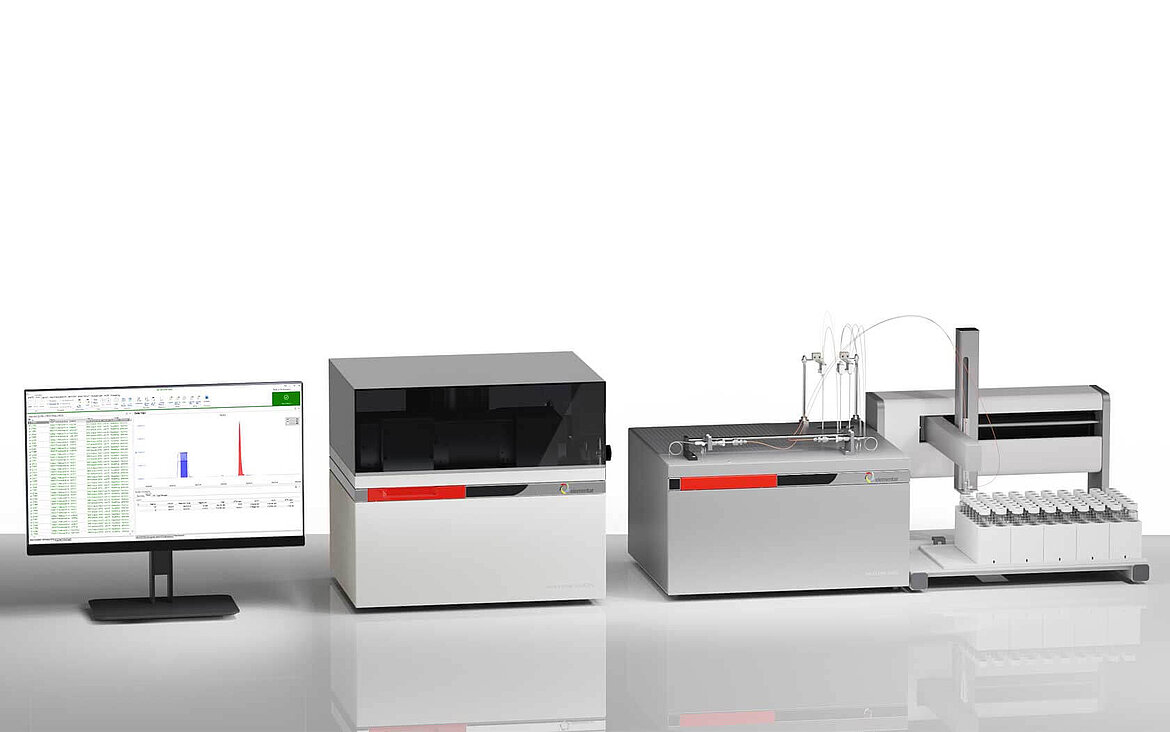

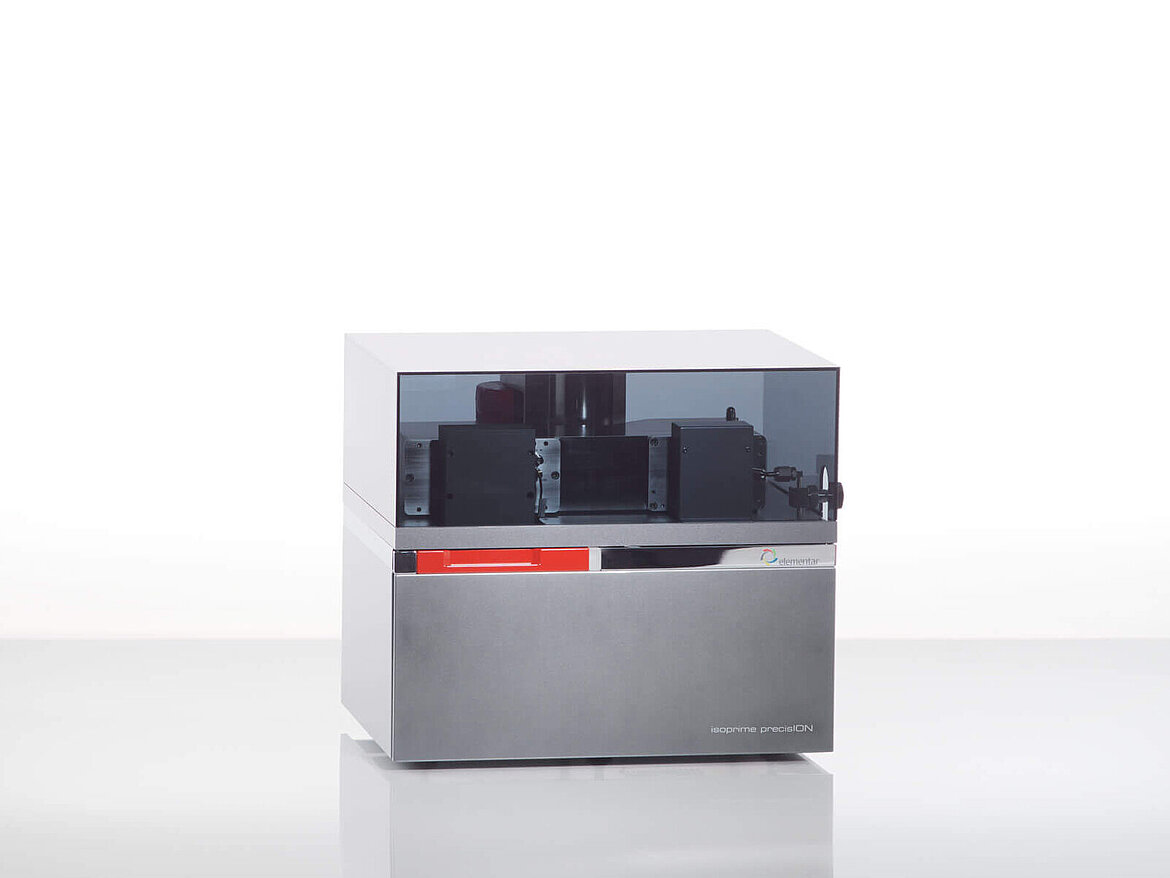

Meet the workhorse in elemental analyzer isotope ratio analysis (EA-IRMS): the vario ISOTOPE select. This elemental analyzer inlet combines reliable results with outstanding robustness. The vario ISOTOPE select is designed for simultaneous carbon, nitrogen, and sulfur isotope ratio analysis in samples with weights of up to 300 mg. Analysis results with highest precision and accuracy are guaranteed thanks to highly efficient gas preconcentration and peak separation. The analyzer also offers the option for δ2H determination of water and convinces with highest system uptime thanks to its low-maintenance design. In combination with one of our state-of-the-art IRMS systems, you will always get the best out of your analyses.

Highlights of the vario ISOTOPE select

Excellent peak shapes and separation with simultaneous NCS analysis

for analysis of very low sulfur contents in high carbon samples (e.g. tree rings)

Low-level δ15N analysis

made possible through our zero-blank sample introduction system

High operating comfort

thanks to a high level of automation and low maintenance

240-position autosampler

for maximum throughput of microsamples

Features

Excellent peak shapes and separation thanks to Temperature Programmed Desorption (TPD)

The vario ISOTOPE select delivers excellent peak shapes and full peak separation in simultaneous NCS analysis mode in less than nine minutes. This is achieved thanks to our patented Temperature Programmed Desorption (TPD) technology, which separates combustion gases using dynamic – not preprogrammed - heating. Because the individual target gases are only released, once the prior sample peak has reached baseline, complete peak separation is guaranteed even for extreme elemental ratios. Additionally, our TPD technology releases gases in a highly rapid and therefore focused manner, resulting in high signal-to-noise-ratios. Together with a high furnace temperature of up to 1,200 °C and jet-injection of oxygen to the point of combustion, our TPD technology provides outstanding accuracy and sensitivity. This enables the detection of very low sulfur contents even in a high carbon sample matrix (such as tree rings), making it the ideal instrument for NCS isotope analysis.

Low-level δ15N analysis thanks to zero-blank sample introduction

Thanks to a zero-blank sample introduction, reliable low-level δ15N analysis is possible with the vario ISOTOPE select. Additionally, the jet-injection of oxygen directly at the sample assures complete combustion efficiency at lowest oxygen consumption for matrix-independent results, even for samples that are traditionally difficult to combust. In conjunction with a state-of-the-art thermal conductivity detector, the analyzer provides an elemental detection limit of < 100 ppm.

High operating comfort through design

The vario ISOTOPE select features a big ash finger as well as separate combustion and reduction tubes, which results in extremely low maintenance and highest system uptime. Whenever maintenance is necessary though, our user-friendly clamp connections ensure a tool-free experience, while the slide-out furnace guarantees easy accessibility and a comfortable working posture.

240 position autosampler for maximum sample throughput

Equipped with a 120 or 240 position autosampler, the vario ISOTOPE select is designed for unattended 24/7 analysis and high sample throughput. The autosampler is reloadable at any time – even when an analysis is being conducted.

Future-proof thanks to 10 years guarantee

Thanks to the outstanding robustness and longevity of our vario ISOTOPE select, we grant a 10-year guarantee on the high-temperature combustion furnace and the thermal conductivity detector cell of the thermal conductivity detector (TCD). With our long-term oriented dedication to technical support, we provide spare parts for a minimum of 10 years. This results in outstanding low total cost of ownership, giving you confidence in return of investment.

Product details

The vario ISOTOPE select is optimized for the analysis of:

δ13C

δ15N

δ34S

δ2H*

* optionally available

Weighing range

Large weighing range: from micro (20 µg) to semi-macro (300 mg soil) sample weight

Element concentration range

Large dynamic range of element concentrations and ratios:

C: up to 7 mg abs.

N: up to 10 mg abs.

S: up to 2 mg abs.

Precision

Elemental performance (external precision, 1σ):

< 0.1 % for C, N, and S

Isotope ratio performance (external precision, 1σ):

δ13C: 0.1 ‰

δ15N: 0.15 ‰

δ34S: 0.2 ‰

δ2H* (HDChrome): 0.5 ‰

Analysis time

~ 3 - 4 min per element, self-optimizing according to element content and sample weight. Depending on sample type, analysis mode, and configuration.

* optionally available

High-temperature combustion unit

Complete sample digestion at up to 1,200 °C (or 1,800 °C at the point of combustion when tin foil is used) with a ten-year furnace warranty. A jet injection of oxygen directly to the sample leads to the highest oxygen concentrations at the point of combustion, as well as low gas consumption. This guarantees 100% recovery even for samples, that are traditionally hard to combust.

Purge and trap chromatography

Separation of gaseous components via our TPD column. This column releases individual gases at different temperatures. The release of a gas is only initiated, when the prior gas peak has reached baseline. This results in perfect peak separation without overlap and automatic optimization of the analysis time.

Detector

Thermal Conductivity Detector (TCD)

Sample introduction

- Integrated 80*, 120, or 240* positions autosampler (for solids and liquids in capsules), reloadable during analysis

- Integrated 2 ml vial, 50 positions liquid autosampler with rinse and waste vial*, reloadable during analysis

Maximum furnace temperature

1,200 ° C (whereby 1,800 °C is briefly reached at the combustion point when using tin foil)

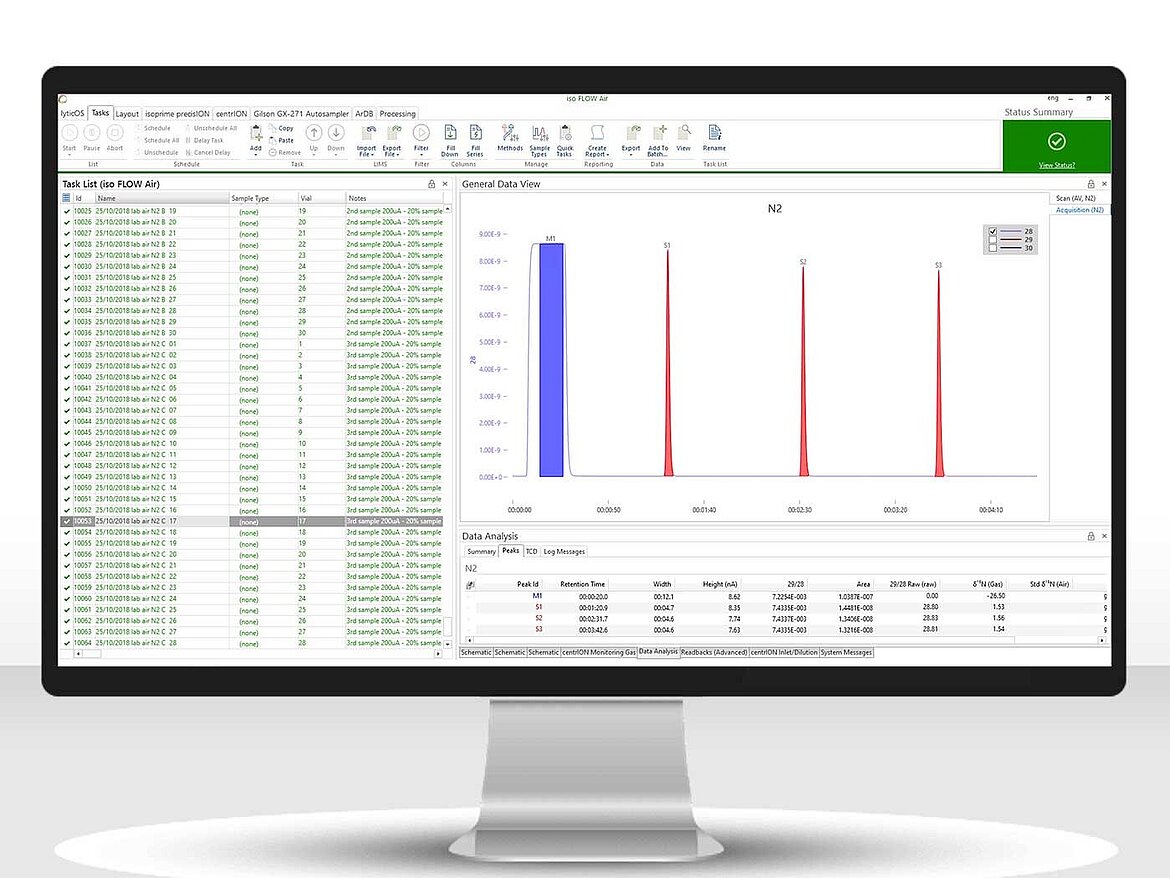

Instrument control

Windows® based lyticOS® Software Suite with LIMS integration and auto sleep and wake-up function for automated and unattended overnight operation.

Required gases

Helium and oxygen

Dimensions

48 x 55 x 57 cm (W x D x H)

* optionally available

Electronic balance:

Balance and elemental analyzer form a system. We offer analytical balances from the leading manufacturers with our instruments. Please contact us for further information.

Sample former and pressing tools:

For simplified sample preparation, we offer a manual tool for compressing samples in tin foil or cups, and a mechanical press for the preparation of pellets with paper wrapping.

Capsule sealing press:

Tool for the exact dosing and gas-tight sealing of tin or silver capsules, for liquid and sensitive samples.

Downloads