Sustainable Polymers: Smart Materials for a Cleaner Future

Plastics are an integral part of our everyday lives – but their success comes at a high price. Millions of tonnes of plastic waste pollute our environment every year, contaminating oceans and endangering ecosystems. To counteract this development, sustainable polymers are increasingly coming into focus. Whether bio-based from renewable raw materials or obtained from recycled plastic, they offer the potential to reduce dependence on fossil resources and significantly reduce the ecological footprint of plastic production.

What are bio-based and recycled polymers?

Bio-based polymers originate (wholly or partly) from renewable raw materials such as sugar, starch, vegetable oils, biomass or even CO₂. Examples include PLA (polylactic acid), PHA (polyhydroxyalkanoates), bio-based polyethylene and the innovative PEF (polyethylene furanoate). They are usually produced using biotechnological processes such as fermentation (e.g. PLA from corn starch, PHA from microorganisms), chemical synthesis from biogenic monomers (e.g. PEF from FDCA, obtained from fructose) or by reformulating existing petrochemical processes1. Recycled polymers, on the other hand, are made from plastics that have already been used – for example, through mechanical recycling (shredding, extrusion) or chemical recycling (breakdown into monomers). One example is polystyrene recycling using the CreaSolv® process2, which recovers high-purity EPS (expanded polystyrene).

Applications and benefits

Bio-based polymers are mainly used in packaging (e.g., PLA films, PEF bottles), textiles, technical components, fibers, films, and injection-molded parts for various industries. The advantages here are that dependence on fossil raw materials is reduced and, at the same time, CO₂ is bound during growth through photosynthesis – at least with regard to the biogenic carbon content. PEF in particular scores highly with its excellent barrier properties for packaging, while PHA and PHB (polyhydroxybutyric acid) are suitable for high-quality injection molded parts due to their thermoplastic properties.

Recycled polymers are often used in everyday items, packaging, insulation boards, and, in rare cases, even as high-quality regranulates or in special processes. The advantages here are savings in energy and raw materials and a reduction in waste and CO₂ emissions by avoiding primary production.

Important contribution to environmental protection and reduction of emissions

Bio-based plastics save CO₂ during production by using biomass as a carbon source – ideally, they only emit as much CO₂ during decomposition or combustion as they previously bound. PEF is a good example of this. Coca-Cola, Danone, and ALPLA are developing bio-based PEF bottles, and the Carlsberg brewery tested the “Green Fibre Bottle3” made from PEF and wood fibers, which keeps drinks cool for longer.

One example of PHB/PHA is Biomer4, a German company that produces PHB granules for precision injection molded parts from renewable raw materials. These are used in automotive engineering, packaging, and coatings.

One example of recycled polymers is the CreaSolv® process2 mentioned above. Developed by the Fraunhofer Institute, this process selectively dissolves polystyrene and enables it to be recovered as high-purity material. A large proportion of the recycled plastic is used to manufacture new packaging for food, beverages, and other products. Mechanically recycled plastic bottles can also be used to produce textile fibers that are used in clothing, carpets, backpacks, and other textile products. Another inconspicuous application is street furniture: benches, trash cans, picnic tables, and other elements of street furniture are increasingly being made from recycled plastics.

Market growth and future developments

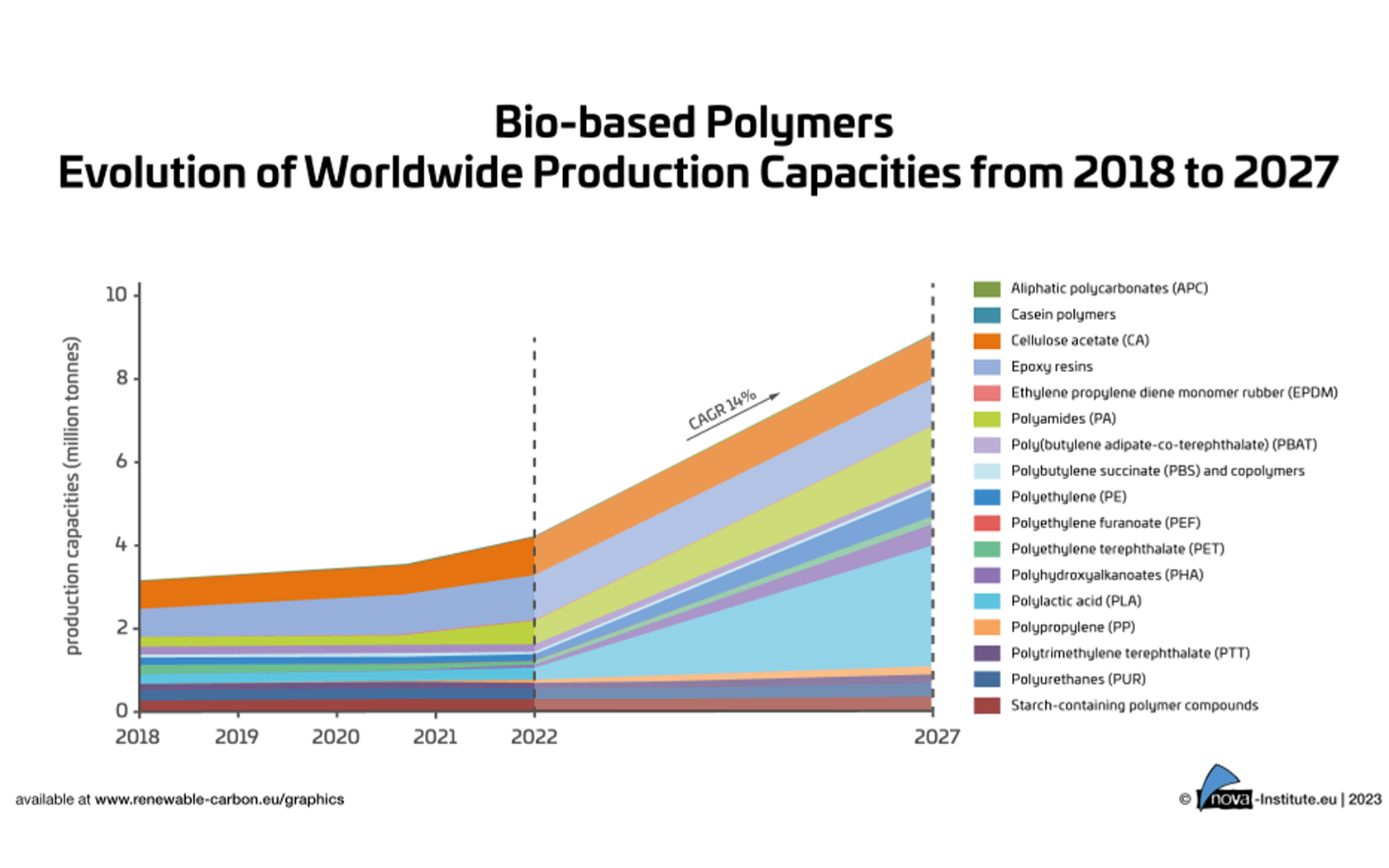

The market for bio-based polymers has been growing significantly for several years. In 2023, around 4.4 million tons of bio-based polymers were produced worldwide - although this represents only about one percent of the global polymer market, the trend is dynamic5. Forecasts predict an average annual growth rate (CAGR) of around 17 percent until 2028, significantly more than conventional fossil-based polymers, which are only growing by two to three percent. The main drivers of this development are increasing sustainability requirements, political support programs, and growing acceptance in the industry. From a regional perspective, Asia currently accounts for the largest share of global production capacity at around 55 percent, followed by North America with around 19 % and South America with around 13 %. Europe also accounts for around 13 % but is losing market share in international comparison – a development that is attributed to a lack of political support and comparatively high production costs6. While targeted legal measures are promoting expansion in the US and many Asian countries, the framework conditions in Europe are less dynamic, which could impair competitiveness in the long term. Certain types of polymers such as PLA, PHA, bio-based polypropylene, and novel casein polymers are currently experiencing particularly high growth rates. In some cases, annual growth rates of up to 40% are expected. The supply of raw materials also appears to be stable: sugar, starch, glycerin, and vegetable oils form the basis of most bio-based plastics. The biomass share required for this is low on a global scale—even with further market growth, it will only account for a fraction of total agricultural use.

In the future, new bio-based monomers such as FDCA (to produce PEF) or castor oil derivatives (as a substitute for petrochemical plasticizers) are likely to expand the product range. At the same time, new large-scale plants are being built worldwide, especially for PLA, with production capacities of more than 160,000 tons per year7. Another important trend is the combination of bioeconomy and circular economy: the aim is not only to use biomass efficiently, but also to reuse it multiple times in closed material cycles. This also brings combinations of bio-based materials and recycling processes into focus in order to further improve the carbon footprint.

What role does elemental analysis play in supporting this sustainable trend?

When it comes to bio-based plastics, it is important for manufacturers, buyers, and certification bodies to know how high the proportion of renewable raw materials actually is. Elemental analysis can precisely determine how high the biogenic proportion of a material's carbon content is. This allows statements such as “50% bio-based” or “100% from renewable raw materials” to be scientifically substantiated.

When it comes to recycled polymers, it is crucial to ensure material purity. Elemental analyses can quantify residues from catalysts, additives, or fillers, for example. This makes it possible to determine whether a regranulate is suitable for high-quality applications or whether further cleaning steps are necessary.

In material development and research into new bio-based polymers, elemental analysis helps to check the chemical composition of prototypes and compare it with the target values. Changes due to aging, UV radiation, or thermal stress can also be detected in this way. In addition, more and more markets are demanding proof of the origin, composition, and environmental balance of plastics. Elemental analysis provides objective, reproducible measurements that serve as the basis for environmental certificates, life cycle assessments, or legal conformity tests.

Conclusion

Bio-based and recycled polymers are key building blocks for a more sustainable plastics industry. They combine resource conservation, CO₂ savings, and innovative material properties - from packaging to technical applications to specialty products. The market is growing significantly faster than conventional plastics, driven by technological innovation and regional government support programs.

Sources

1 https://www.bayern-innovativ.de/emagazin/detail/de/seite/biobasierte-polymere-und-ihre-anwendung

2 https://www.creasolv.de/de/der-prozess.html

3 https://www.about-drinks.com/carlsberg-praesentiert-die-neueste-version-der-fibre-bottle/

4 https://www.biomer.de/IndexD.html

5 https://www.k-zeitung.de/biobasierte-polymere-auf-der-ueberholspur

6 https://www.presseportal.de/pm/130679/5730584

7 https://www.farbeundlack.de/nachrichten/markt-branche/starkes-wachstum-bio-basierte-polymere/

Do not miss any new articles

NEWSLETTER

We will constantly publish new blog articles. Register for our newsletter to stay up-to-date and get informed about latest blog articles, news and trends.