GMP analysis without risks or side effects

GMP? What does this abbreviation mean?

This stands for "Good Manufacturing Practice". It is a minimum standard that manufacturers of cosmetics, food, beverages, food supplements and, above all, producers of pharmaceuticals must adhere to. GMP is an absolute must, especially in the essential production of medicines. After all, innovative vaccines, chemotherapeutic agents, beta blockers and many other pharmaceuticals help us to stay healthy or get well. It is therefore of the utmost importance that we can rely on the safety and highest quality of pharmaceutical products and their active ingredients.

Over the past century, the concept of "Good Manufacturing Practice" (GMP) has emerged as a pivotal requirement for ensuring the safety of pharmaceuticals worldwide. The term "Good Manufacturing Practice" was first introduced by the Food and Drug Administration (FDA) in 1962. In 1968, the World Health Organization (WHO) published the inaugural set of official GMP guidelines. These have been subject to continuous updates since the 1980s.In accordance with these guidelines, manufacturers and suppliers are thus obliged to define and comply with a binding, multi-stage authorization process prior to the launch of a medicinal product on the market. The concept of good manufacturing practice (GMP) encompasses a number of key areas, including guidelines for the operation of production facilities, process safety, hygiene measures, logistics, and the validation of devices and associated documentation. In Germany, the application of GMP guidelines is enshrined in the German Ordinance on the Manufacture of Medicinal Products and Active Pharmaceutical Ingredients (AMWHV).

How is it verified that companies comply with GMP standards?

In some instances, unannounced audits are conducted by the local GMP inspectorates to verify compliance with the established guidelines. In the event of non-compliance, production may be halted and medicines withheld, and penalties with serious financial consequences may be imposed. In Europe, for instance, the European Medicines Agency (EMA) is responsible for coordinating these audits. The United States follows a similar approach, with the U.S. Food and Drug Administration (FDA) acting as the U.S. equivalent of the European Medicines Agency (EMA) in ensuring compliance with GMP guidelines.

It is a legal obligation for all manufacturers of medicinal products destined for the EU market to comply with the GMP guidelines, regardless of the location of production. It is incumbent upon companies to ensure that the quality of medicines is absolutely flawless and that nothing is left to chance. It is therefore essential that consumers and patients can rely on the quality of the medicines they take. This requires that all parties involved in the production process, including manufacturers, employees, laboratories, warehouse workers, transporters and pharmacists, adhere to the highest standards of quality and reliability.

The role of analytics for GMP

Analytical instruments for organic elemental analysis and for the determination of total organic carbon (TOC), for instance, assist pharmaceutical manufacturers in crucial tasks such as quality control of the concentration of active ingredients in pharmaceutical products. In this context, manufacturers of analyzers must also address the GMP guidelines in a comprehensive manner.

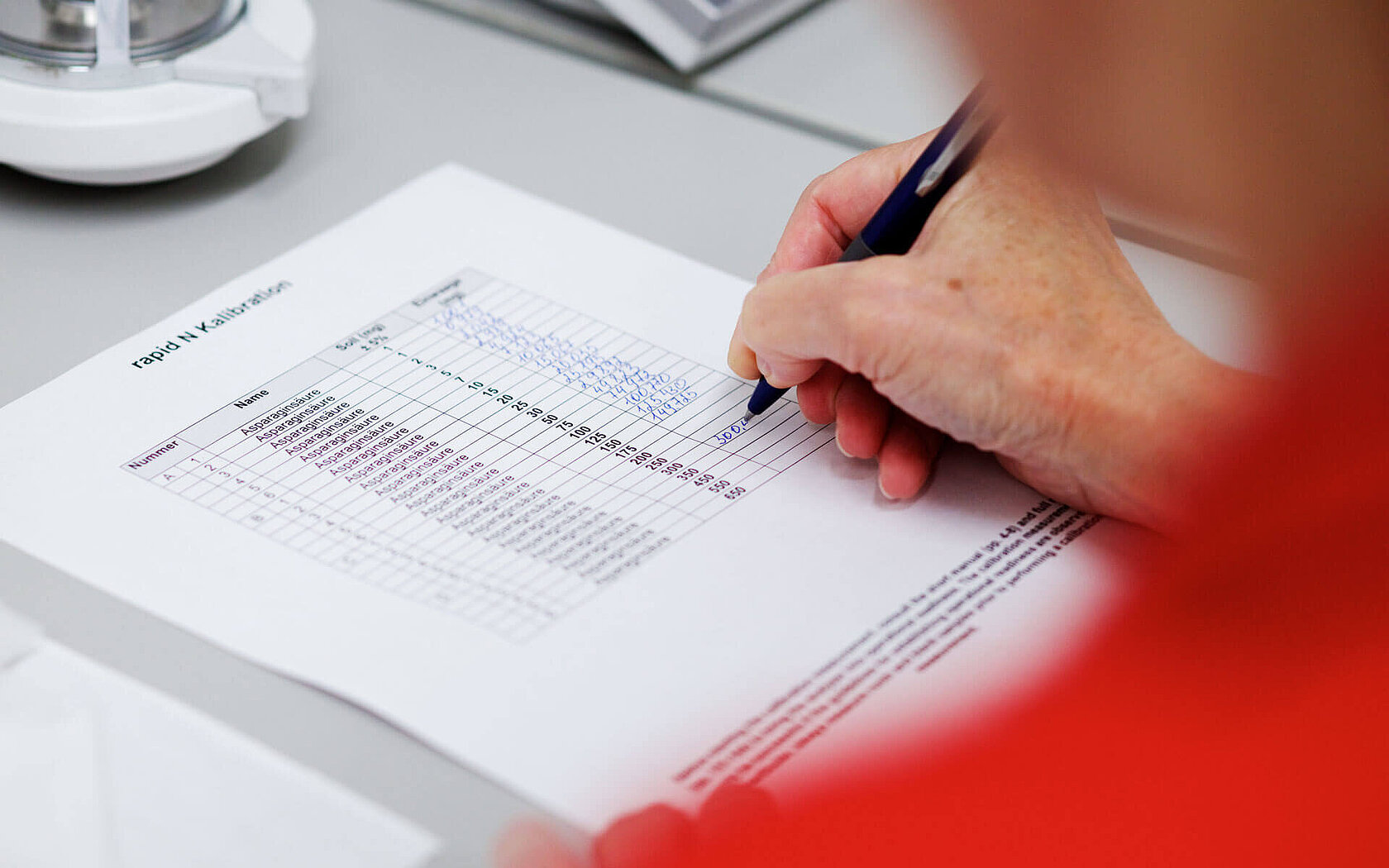

The qualification of instruments represents a fundamental pillar of the GMP guidelines. The installation qualification (IQ) must demonstrate that the analyzers have been installed, operated and are functioning in accordance with the manufacturer's specifications.

Furthermore, the prescribed operational qualification (OQ) of the analyzers must be carried out at regular intervals. This process monitors and documents the correct functioning of the analyzers in accordance with the operating specifications. One beneficial consequence of this approach is the assurance of optimal analytical performance and maximum system availability, which increases sample throughput and reduces costs.

To be continued...

This blog article provides only an initial insight into GMP. Further articles on the subject of GMP will be published in due course, including specific application examples for different types of analyses and a look into the future, such as how digitalization will affect the GMP environment. Stay tuned, as GMP is not a static or one-off activity, but a continuous and ongoing process that requires constant monitoring, evaluation and improvement. To ensure you do not miss future articles, we invite you to subscribe to our newsletter to receive future updates.

In the meantime, you can further explore the topic in our GMP Guide. You will also learn how to optimize your analysis processes in the pharmaceutical laboratory in accordance with GMP regulations.

GMP Guide: Ready for the audit

In this GMP guide, we collected information for you how to ensure GMP conformity of your analytical processes with qualifications, software and services. Furthermore, it contains application examples in the field of CHNOS analysis of different pharmaceutical samples, peptide content analysis, TOC analysis and cleaning validation as well as ADME studies in the product development phase. You will also find out how we can support you in the GMP-regulated environment with various services and worldwide contacts.

DOWNLOAD YOUR COPY

Fill in the form to receive your download link per e-mail.

Your contractual consideration for the free provision of the download is the subscription to our personalized newsletter. By clicking on the “download now” button, you therefore declare your acceptance of the receipt of personalized newsletters by e-mail by Elementar India Pvt Limited and its group companies as well as the evaluation of your user behavior in this regard and - if available - the merging of this data with your data in our customer database.

In order to receive newsletters from our group companies it is necessary to transfer your above-mentioned personal data to these companies. The data transfer is contractually required.

You are aware that the subscription to our personalized newsletter represents the contractual consideration that you provide for the free provision of the download. You can unsubscribe from the newsletter at any time with effect for the future. You can object to the future use of your data for advertising purposes at any time. For further information, please refer to our privacy policy.

Do not miss any new articles

NEWSLETTER

We will constantly publish new blog articles. Register for our newsletter to stay up-to-date and get informed about latest blog articles, news and trends.